Our lamination-Champions

Vlight basic

Vöhringer has its roots in woodworking and processing. An essential pillar was and is the coating of panel materials for the caravan industry. The production and wrapping of profiles and furniture parts, as well as the use of polyurethane as a waterproof lightweight construction material, make Vöhringer a leading system supplier.

With today's production possibilities and materials used, Vöhringer offers its products across all industries. The production is divided into four main areas.

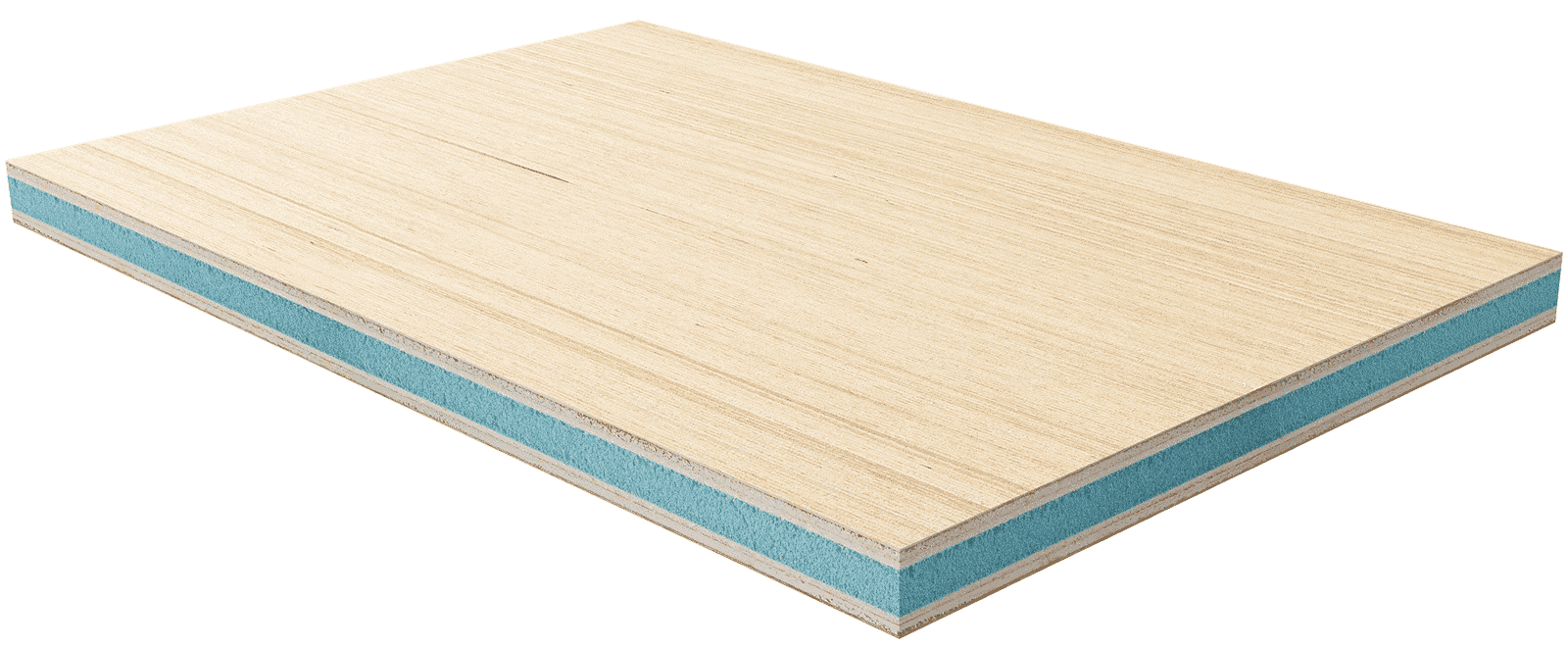

Panel lamination

With 50 years of experience, Vöhringer is the top address in the area of flat lamination. It all started with the first paper-coated plywood panels, with which we opened up the new lightweight construction dimension in the caravan industry.

This spirit of trying new things and developing oneself is still an important part of being able to offer our customers innovative products and thus to set benchmarks.

Whether industrial dimensions or individual special solutions, our development department makes requests ready for series production. We cover everything from plywood to MDF, HDF, chipboard and innovative sandwich and plastic panels.

When it comes to surfaces, you can choose whether it is paper, foil or laminate from super matt to high gloss. With eight state-of-the-art machines, experienced, long-term and committed employees, we are perfectly equipped to meet your needs.

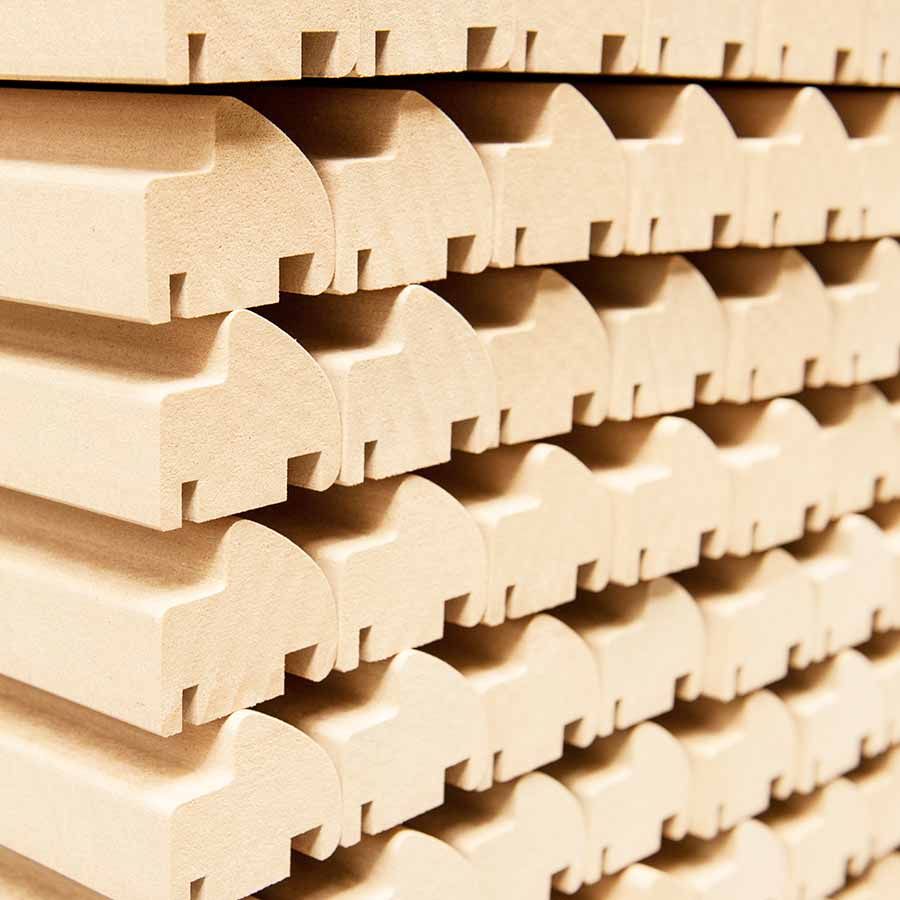

Furniture parts and manufacture

Furniture construction par excellence. Let our customer-specific furniture production become the building block of your success. Classic furniture construction combined with innovative lightweight construction is one of our specialties. Our products can be found in the caravan and motorhome industry. Even emergency vehicles benefit from our know-how. We manufacture two- and three-dimensional furniture fronts, free forms such as office desks and postforming elements - just-in-time and in Vöhringer quality.

Since we manufacture many primary materials in-house, we are very variable and can develop the best possible solution together with you.

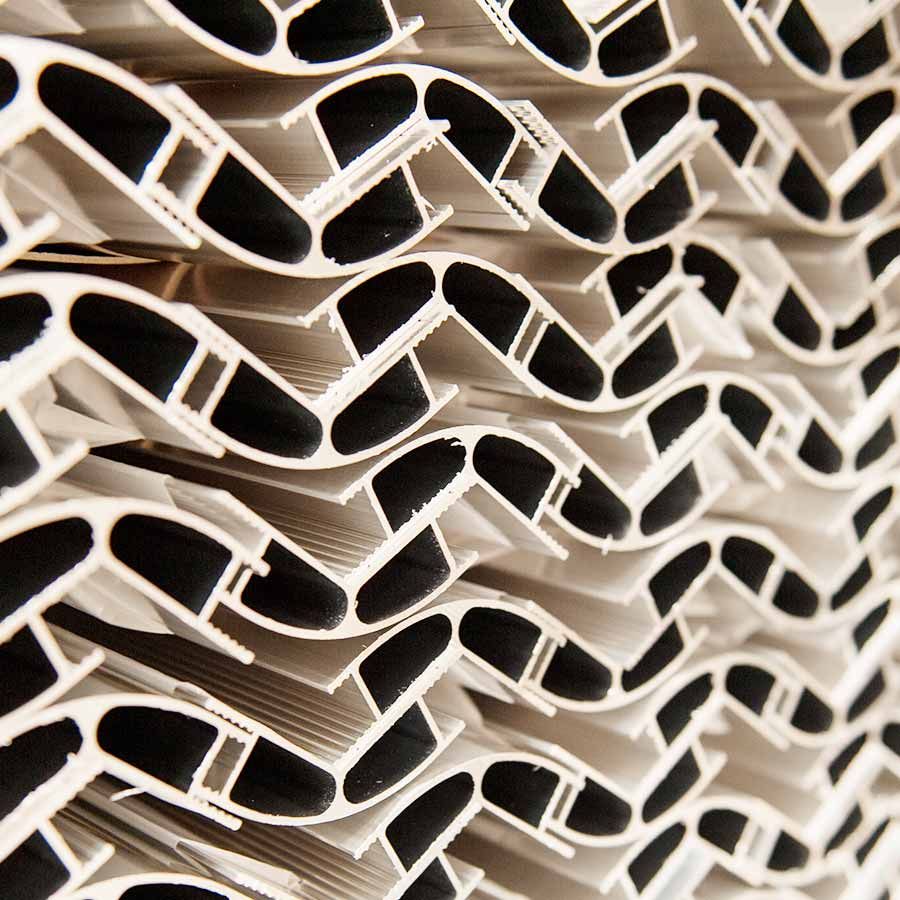

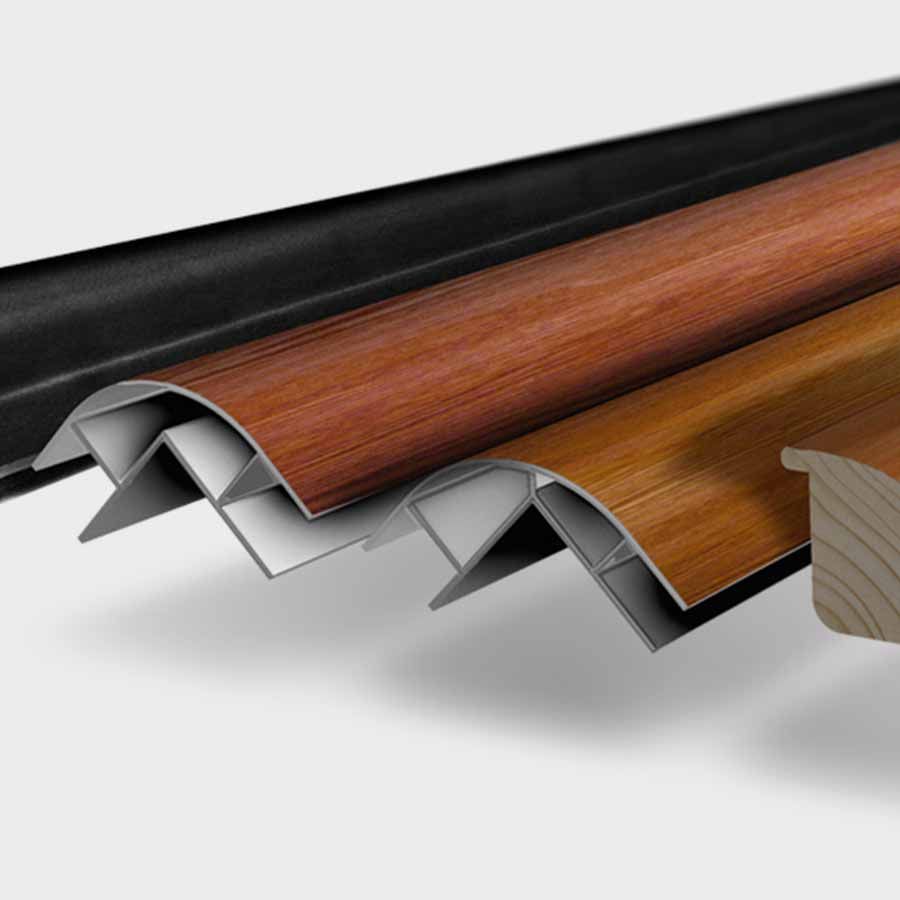

Wrapped profiles and mouldings

Another specialty is the manufacture and wrapping of profiles. We manufacture these tailor-made. Choose profiles made from Obeche, MDF, PU, PVC or aluminum. On request, we can then coat them with a decor of your choice.

The all-inclusive service, from the manufacture of the profile milling cutters to the final CNC machining, comes from a single source. Up to 640 mm wide on request.

Polyurethane

Our PU products are characterized by the latest polyurethane technologies. Because of its extreme versatility, this material is ideal for an economic production and individual design. With different systems the foam density may be adjusted depending on the later use.

With our hard foam products, you can decide if you wish to have straight batten or shaped construction parts. With inserts or screw sockets, painted or covered with 3D foils, You have the choice.

Robots ensure particularly consistent quality in PU production during the injection process. The PU foam materials are mixed in the injection nozzle and can be directly documented and controlled in order to maintain consistent material properties.

Consistent premium quality is ensured

Vöhringer GmbH & Co. KG

In Aufzügen 11

72818 Trochtelfingen

Germany

-

+49 7124 9298-0

-

This email address is being protected from spambots. You need JavaScript enabled to view it.

Monday - Friday

8:00 a.m. – 12:00 p.m

1:00 p.m. – 5:00 p.m

Monday - Thursday

7:00 a.m. – 12:00 p.m

1:00 p.m. – 2:00 p.m

Friday

7:00 a.m. – 12:00 p.m

Are you a customer, new customer or supplier? Are you interested in Vöhringer lightweight solutions?

Then you will find the right contact here who will be happy to help you.